Importance of Ceramic Insulators in Energy Sustainability

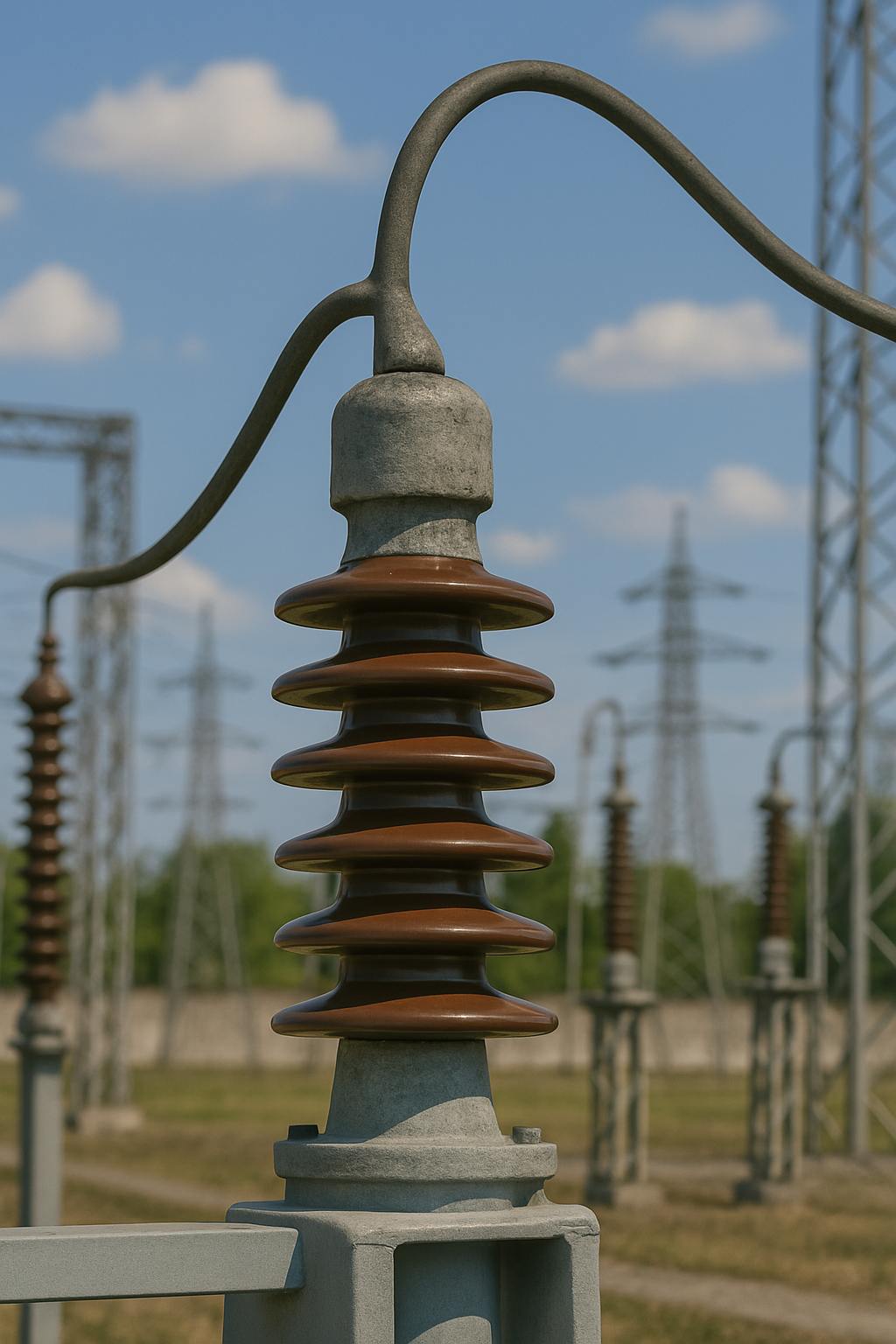

Ceramic insulators play a crucial role in energy sustainability by providing durable and efficient solutions for electricity transmission. These components are essential for ensuring the safety and efficiency of electrical grids, which in turn helps reduce energy losses.

The durability of ceramic insulators is one of their main benefits. Unlike other materials, ceramics are highly resistant to extreme weather conditions, which extends their life span and reduces the need for frequent replacements.

Additionally, ceramic insulators are known for their resistance to corrosion, making them ideal for use in industrial and coastal environments where other materials might deteriorate quickly.

The use of ceramic insulators also contributes to energy efficiency by minimizing energy losses during transmission. This is especially important in a context where energy demand continues to grow, and efficiency becomes a priority.

- Durability and resistance to extreme conditions

- Reduction of energy losses

- Resistance to corrosion

- Contribution to energy efficiency

Materials and Manufacturing Processes of Ceramic Insulators

The manufacturing of ceramic insulators involves the use of natural materials such as clay, quartz, and feldspar, which are abundant and have a low environmental impact. These materials are selected for their insulating properties and their ability to withstand high temperatures.

The manufacturing process begins with the mixing and molding of these materials into specific shapes, followed by a high-temperature firing process that strengthens the insulator’s structure. This process ensures that the insulators can withstand significant electrical stresses.

The firing technology used in the production of ceramic insulators has advanced significantly, allowing for greater energy efficiency in the manufacturing process. This not only reduces energy consumption but also decreases associated carbon emissions.

Additionally, manufacturers are adopting recycling and material reuse practices to minimize waste and promote sustainability in the production of ceramic insulators.

- Use of natural and abundant materials

- Efficient firing process

- Recycling and reuse practices

- Reduction of carbon emissions

Contribution of Ceramic Insulators to Emission Reduction

Ceramic insulators significantly contribute to reducing greenhouse gas emissions by improving the efficiency of electrical grids. By minimizing energy losses, the amount of energy that needs to be generated is reduced, thereby decreasing emissions associated with electricity generation.

Compared to other types of insulators, ceramic ones have a lower carbon footprint over their lifecycle. This is due to their durability and the cleaner manufacturing processes used in their production.

Moreover, ceramic insulators are recyclable, which means that at the end of their life cycle, they can be processed and reused in the manufacture of new products, thus reducing the need to extract new materials.

The use of ceramic insulators in critical infrastructures like electrical transmission grids also helps prevent failures that could result in blackouts and, consequently, an increase in emissions due to the need for emergency power generation.

- Improvement of energy efficiency

- Lower carbon footprint

- Recyclability and reuse

- Prevention of failures in critical infrastructures

Case Studies: Successful Implementation of Ceramic Insulators

A notable example of the successful implementation of ceramic insulators is the modernization project of the electric grid in Spain, where old insulators were replaced with ceramics, resulting in a 15% reduction in energy losses.

In Brazil, the adoption of ceramic insulators in high-voltage transmission lines has improved grid stability, reducing power outages by 20% and increasing customer satisfaction.

Another success case is found in India, where ceramic insulators have been crucial in withstanding extreme weather conditions, ensuring reliable electricity supply in rural areas.

These cases demonstrate how ceramic insulators not only improve efficiency and sustainability but also strengthen electrical infrastructure in various regions worldwide.

- Reduction of energy losses in Spain

- Improvement of grid stability in Brazil

- Reliable electricity supply in India

- Strengthening of electrical infrastructure

Innovations and Future of Ceramic Insulators

The future of ceramic insulators is marked by technological innovations aimed at further improving their efficiency and sustainability. One area of development is the integration of composite materials that enhance strength and reduce the weight of the insulators.

Another innovation is the use of smart technologies that allow real-time monitoring of the insulators’ condition, facilitating predictive maintenance and reducing the risk of failures.

Advances in nanotechnology are also being explored to improve the insulating properties of ceramic materials, which could lead to a new generation of more efficient insulators.

These innovations not only promise to improve the performance of ceramic insulators but also contribute to sustainability by reducing the environmental impact of their production and use.

- Integration of composite materials

- Smart technologies for monitoring

- Advances in nanotechnology

- Contribution to sustainability

Economic Impact of Ceramic Insulators on the Electric Industry

The use of ceramic insulators has a positive economic impact on the electric industry by reducing operational and maintenance costs. Their durability and resistance to adverse conditions decrease the frequency of replacements and repairs.

Additionally, by improving energy efficiency, ceramic insulators contribute to the reduction of costs associated with electricity generation and transmission, resulting in significant savings for electric companies.

The adoption of ceramic insulators can also boost competitiveness of companies by enabling them to offer more reliable and efficient services, which is crucial in an increasingly competitive energy market.

Finally, the use of ceramic insulators supports compliance with environmental regulations, avoiding fines and sanctions, and improving the corporate reputation of companies implementing them.

- Reduction of operational and maintenance costs

- Improvement of energy efficiency

- Boost to business competitiveness

- Compliance with environmental regulations

Ceramic insulators are essential components in modern electrical infrastructure, offering significant benefits in terms of sustainability, efficiency, and durability. Their use contributes to emission reduction, improves energy efficiency, and supports compliance with environmental regulations. Through technological innovations and sustainable practices, ceramic insulators continue to play a crucial role in the transition to a more sustainable energy future. Their successful implementation in various projects around the world highlights their importance and potential to transform the electric industry.